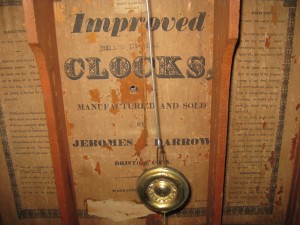

A pilaster clock with wooden movement by Jeromes & Darrow (1828-1832) came in for repair. The owner said she had taken it to a clock repair person who told her the clock could not be fixed and was just good to be thrown away.

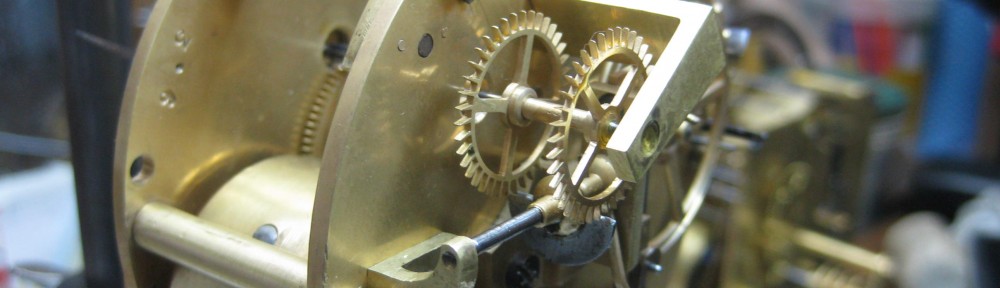

Upon examination, I discovered that some teeth were broken and needed to be repaired to have the slight chance of running again.

The following pictures show how teeth can be replaced. Although wood can be used to fit a new tooth where one is missing, I chose to fill the gap with epoxy glue.

The method is simple: insert a pin in the core of the wheel; make a mould of a part of the wheel with plasticine; place the mould over the broken tooth and pour epoxy glue in the empty hole. Let dry overnight and … Voilà!, you’ve got a good solid tooth.

The same method can be used to repair broken leaves on a pinion. In fact this is an easier way to do it and you get a more solid repair than trying to insert a wooden leaf.

Both gears were returned to the movement and the clock is now running properly. I m pleased with the result of this repair and so is the owner of the clock which is an interesting piece of horological history.

If you try this at home, use some plasticine underneath your gear to make sure you don’t epoxy your gear to the table.